Dexter144

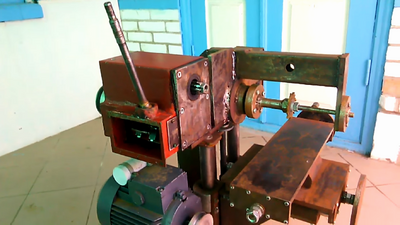

https://www.youtube.com/watch?v=kCldgHJ5e9M,(tailstock pt.5) channel Dexter144 part3 lathe build with two pillow block bearings. Aligning bearings with round shaft(6min). Mod the design by installing an additional tapered roller bearings opposite each pillow block, allowing for axial loads and increased radial load bearing surface area(use JBWeld or cement/epoxy for vibration damping(Shimming).

https://www.youtube.com/watch?v=gjNuzIIXJeY lathe headstock design

https://www.youtube.com/watch?v=Y0pBPqj5lR8 another spindle design

https://www.youtube.com/watch?v=b8G55W060dc part 10 , replaced self alignment pillow block bearings with vehicle angular roller bearings for axial load. Probably the easiest diy way to make a lathe, hence migrating dexter144 to the top.

Turek

wide beds for high spindle

https://www.youtube.com/watch?v=_Jf0F6CiQcQ Hey, you're doing a great job there! The only thing I don't personally like is the center-height to beds' width ratio. The more the height you set your spindle at without either widening the beds or reinforcing the overall structure, the lighter the duty the machine will be able to support during normal operation before it starts to flex/vibrate.https://www.youtube.com/watch?v=LY6wmHL48H0 . quill lock, Shimming of any plane perpendicular to another in the x,y and z axis is done with a granite cube and describes method of using Moglice or JB Weld to create a headstock.(Stefan Gotteswinter anneals copper wire, cutting it up into small pieces and spreads it over the base plate before injecting the moglice. This creates a buffer space allowing for three point alignment in the plane as the triangle bolts are tightened down, providing no slip grip and cavity free surface area mating, which eliminates chatter on the work piece from any vibrations not damped by the cast iron casting. ) Any number of orthogonal and parallel planes or axis are created with a granite cube. Lathe#accidental_science uses a 1:1 cement, epoxy mixture as cheaper alternative to Moglice. It forms a paste that takes 24 hours to cure allowing for the alignment of the headstock with lathe bed with lathe head tramming method. channel floweringelbow 25% slow cure epoxy, 69% iron powder, 5% aluminium oxide, 1% magic dust? for mating two pieces of metal. When aligning two elements, take dial indicator reading as you tighten, not afterwards. https://www.youtube.com/watch?v=cqYJS27aC4w liquid slow cure epoxy for rail base, linear rails need a shoulder. See Hand_scraping#ways for scraping column ways.

liquid slow cure epoxy for rail base, linear rails need a shoulder.

. See Epoxy_granite#tramming.

imbus

https://www.youtube.com/watch?v=Qbawy6Mp1Hc welding steel together needs destressing in an oven at 560c, cast iron is preferred, but needs to be tapped and bolted together.

granite

https://www.youtube.com/watch?v=d3f3vknWj-w high precision cnc with granite from https://www.youtube.com/@PiotrFoxWysocki

https://www.youtube.com/watch?v=sbincod2e3c DIY Precision Black Granite CNC Machine from scrap.

Part2 - Lapping, Grinding and drilling holes. from https://www.youtube.com/@WorldofMachines

@GBWM_CNC

https://www.youtube.com/watch?v=vlNlzDfhprY from https://www.youtube.com/@GBWM_CNC

thinhlinhkiencnc

https://www.youtube.com/watch?v=ycH4IcA4gMk use 20min actuator for Linear actuators design from https://www.youtube.com/@thinhlinhkiencnc

clough42

https://www.youtube.com/watch?v=FTs9GygRQ-U&list=PLDlWKv7KIIr90ZZ7Zqt-ge5nVVdS3WVgg and electronic lead screw github by clough42

firstchip4349

https://www.youtube.com/watch?v=CYNV6W7jOLE firstchip All plain metal(playlist vids), not cast iron, links to plastic PEEK Zedex(alternative to expensive turkite) strips glued( polyethylene ) to steel ways and held fast with brass pins as steel on steel will wear down and it can't be Hand scraping, used an angle grinder.

https://www.youtube.com/watch?v=t-AoY6yKlMs mill build

journals

https://my.mech.utah.edu/~bamberg/research/PrinciplesOfRapidMachineDesign/Principles%20of%20Rapid%20Machine%20Design.pdf principles of Rapid Machine Design thesis. Eberhard Bamberg M.Sc., Advanced Manufacturing Systems Brunel University, 1993. p.83 The use of polymer eliminates the need for precision surfaces at the joint between the bridge and the base. Instead, the bridge is set upon an O ring which is laid along the perimeter of the joint. p.111 split tube epoxy damping, concrete damping. p.144 use round tubes instead of square tubing.

gbwm

Tchannels joined with flatbar, reinforced with Uchannel sections.

https://www.youtube.com/watch?v=vlNlzDfhprY Step model of this machine is available for people who joined the channel support membership. I might do "detailed" plans for it but at this moment I share just the step file. Inspired by https://www.youtube.com/watch?v=E4GT7Atq7ug&list=PLfHKOcnbjzKwIgHi_YfNaqDZzhY0oARtp which uses H beam is made out of two T beams welded together with large flatbar and reinforced with square tube or Uchannel sections. Zaxis column are angle iron pieces with flatbar diagonally in center making a side to side square tube like structure drilled and tapped for linear rail each(6min33), it is more rigid than just a square tube for the same dimension. The back of the Zaxis column is reinforced with Uchannel that has a section removed at an angle. (7min21). Large rigid table for hoisting Yaxis from the ground for further wedling and drilling, is built out of Uchannels(9min).

The Yaxis base is so heavy that the table is held rigid in the center with a hydraulic jack. In video nr.2 of the playlist the Yaxis is lifted on the rigid table built in vid nr.1 . It's not clear how the ways were milled for the linear rails(see Moglice, Shimming, hand scraping). The video is in Polish, Google's algorithms don't list if for an English audience and the low view count betrays that is probably one of the best lathe and mill videos, showing clearly how to build a large heavy duty mill out of scrap Uchannels and Tchannels.

Dowlpin spacing of linear rails guid pin linear rail vid.9 vid1 to 14 pictures at https://nippybox.com/v/625175 in zip file. See picture Screenshot(234).png for screw/dowlpin combo to straighten the guide rail(is forms a snake pattern its default state).

https://www.youtube.com/watch?v=cqYJS27aC4w similar type heavy industrial design channel, very slow(several months) concrete cure(no epoxy) for very cheap vibration damping solution. floweringelbow

CNC heavy duty DIY CNC milling machine playlist 33vids.

lets learn something

https://www.youtube.com/watch?v=SmQ6uNSkGdE DIY mill , angular roller bearings to make spindle and see

rather b welding roller bearings. Lathe headstock build with angular roller bearings from https://www.youtube.com/watch?v=gjNuzIIXJeY (channel Mr. Rany Homemade)

https://www.youtube.com/watch?v=a6a5HTsYCSY from channel Lets learn something

https://www.youtube.com/watch?v=-9o0GsKqx-M placing two thrust bearings.

chipload

https://www.youtube.com/watch?v=J7QdpF-mVbc&list=PLBZ7MNtrlcsMx6BnlLjA1MIX_2MO5rzRU part 7 using epoxy filled metal for concrete lathe bed(http://www.epox.de) . See Epoxy granite for super strong epoxy with diamonds by channel Tech ingredients.

https://www.youtube.com/watch?v=cnQjjkuJXWc STUDER has been manufacturing machine beds from its own specially developed Granitan® mineral casting for decades. In comparison with machine beds made from iron-based materials, Granitan® machine beds have a more favorable thermal and better cushioning behavior. Temporary temperature fluctuations are largely compensated by the favorable thermal behavior of Granitan®. The excellent cushioning behavior of the machine bed ensures outstanding surface quality of the ground workpieces. Far fewer energy and raw material resources are consumed in the manufacture of Granitan®, in comparison with the manufacturing process for steel. https://www.studer.com/en/

epoxy

https://www.youtube.com/watch?v=mc2DrNNfS-c from https://www.youtube.com/@GameofCNC_PLOT

https://www.youtube.com/watch?v=GzBAJTgo3QU from https://www.youtube.com/@GleenoIT

danger diy

https://www.youtube.com/watch?v=pAKDnjqIEF4 Building a DIY CNC metal lathe with CNC control using Mach 3. Using steel, aluminum, bolts, nuts, and some parts from Amazon i created a 10 inch x 24 inch CNC metal lathe. Using a somewhat on the fly design of a metal lathe with a CNC controller. This video goes over the lathe build and there is a separate video (offered at the end and during the video) for the CNC drive that also covers a recap of the design of the lathe. I also thought it would be a good idea to hold a piece of aluminum I was sanding with a flap disc... It wasn't a good idea, but a painful lesson as I almost cut off my left thumb.

spindle

https://www.youtube.com/watch?v=q7qRK0xWVzc bridgeport clone, cast iron hydrolic cylinder from c330 tracktor for spindle by steelcraft , https://www.youtube.com/@SteelCraft99 12 part milling machine build

https://www.youtube.com/watch?v=HOIo2V8LRCk&list=RDCMUCEaov0EXiRIZ1vqYKO6Oa-w&start_radio=1&rv=HOIo2V8LRCk&t=0 spindle design channel PG BR

https://www.youtube.com/watch?v=fZjEoP9w8bA&list=RDCMUCNkxUXuAh2RBEjwCLWz5OwQ&start_radio=1&rv=fZjEoP9w8bA&t=0 spindle design channel Nilton Polydoro

robrenz

https://www.youtube.com/watch?v=grUdsTTRGl4 precision spindle make

https://www.youtube.com/watch?v=LUggzM0JOlI ultra precision spindle build

https://www.youtube.com/watch?v=Pmplff_f5pI suburban tool, what it takes to repair spindle.

https://www.youtube.com/watch?v=Letjbux6qxA making collet blocks by the shed dweller'

twist

https://www.youtube.com/watch?v=IbfUaeUp7RY refs steve jordan channel

https://www.youtube.com/watch?v=CLknmNHJiQ0 channel steve jordan

https://www.instructables.com/Building-a-Sturdy-Lathe-Stand/

ivan mechanic

https://www.youtube.com/watch?v=YRZBgbgYMik&list=RDCMUC9uD8Msx1GfFHT6BPKUwTsw&index=4 uses the lathe spindle shaft to align the angular roller bearings. Allows you to have the spindle made first at a professional machine shop for your DIY headstock construction. Vid.4 out of playlist

francisco

https://www.youtube.com/watch?v=Y8ebK9UlHKE Francisco Murcia Projects Learn to make a Milling Machine Homemade (Z axis) step to step in a simple and practical way. Everything is made with small machinery.

https://www.youtube.com/watch?v=_hwBLD4waT8 part.1 milling table

https://www.youtube.com/watch?v=ss0pxgf5Z34 final part, he can't figure out how to use playlists.

Russian hacks

https://www.youtube.com/watch?v=uVlrfFkRLZg stepper on crosslide of lathe Олег Певцов

https://www.youtube.com/watch?v=5-ZVJjMU1hs cross feed by ivan mechanic

https://www.youtube.com/watch?v=41EU1znG8P4 esting the function of the lathe that I have made in stages, this lathe is only about 70% and there are many more that must be improved.Thank you for watching my channel, like and subscribe to this channel, hope it will be useful

https://www.youtube.com/watch?v=uVlrfFkRLZg cross slide tapered cutting with stepper

https://www.youtube.com/watch?v=Y7OT4vFevxM with no music

https://www.youtube.com/watch?v=pcOJBrLODSE ana diy

https://www.youtube.com/watch?v=YR21-fnpdNs diy lathe from Good master channel

https://www.youtube.com/watch?v=E7pzYEUX84k, https://www.youtube.com/watch?v=7SXuS7nnqe8 milling dove tails grinding stone dove tails

https://www.youtube.com/watch?v=5-ZVJjMU1hs grinding stone dovetails.

https://www.youtube.com/watch?v=718Dyz5EG2o flatbar bolted to bedway.

https://www.youtube.com/watch?v=WXGbV2l9gN0 tailstock design by Самодельная задняя бабка.

https://www.youtube.com/watch?v=kjVCVxdQfz0

https://www.youtube.com/watch?v=z03c1RuHIvc

https://www.youtube.com/watch?v=QJtmXJZqfOY

https://www.youtube.com/watch?v=HRh40jICW8c

Homemade lathe machine

|

https://www.youtube.com/watch?v=C01EHSxkcac part18 latest update 4 apr.2022

https://www.youtube.com/watch?v=u0u_aqDPwNo eight part series by channel Homemade lathe machine

https://www.youtube.com/watch?v=hoPwMmqA6vw part 13 home made mill machine

https://www.youtube.com/watch?v=9i_9a5FHCyI&list=PLg8MjgZpAh_JIMB2eZssLetHYUmWT62WU metal shaper and https://www.youtube.com/watch?v=oxzIVbL2ONw from another channel

https://www.youtube.com/@rcmodelsfullmetal474 rc truck axel from same author and https://www.youtube.com/watch?v=cyV8-4VgfEg alternative design with pvc and https://www.youtube.com/watch?v=lhXfKN-UO4g swing arm from https://www.youtube.com/@makeandride and https://www.youtube.com/watch?v=7TMYHnDRCyw suspension and https://www.youtube.com/watch?v=vxY2WXgjlFo clone of same atv idea

mill

| https://www.youtube.com/watch?v=i4q95Czq7pc This is full video of my CNC milling machine build, if you have seen other 5 videos this would be repeat for you. however I am listing some measurements and parts list in description. Build time: About 500 hours. Build cost: About $4500 https://www.youtube.com/watch?v=jY0gtToK91U Milling machine build in three days. |

rolandvanroy

|

https://www.youtube.com/watch?v=Lzytexbrdlg Building this lathe from scratch was a challenge. I'm not a mechanical engineer, so the build was based on gut feeling and materials I had available. Still I'm quite happy with the end result, even though my lathe does not have the full functionality of a real lathe. But it is small, quite power full and can still handle up to 30mm diameter metal rods through the spindle boring hole. Now I finally can continue my work on the new Linear actuators for my 5th generation motion platform. https://www.youtube.com/watch?v=rHEE_eNhZJ4 mill build |

Dovetail milling

| Dovetail milling | Slide dovetail |

|---|---|

|

|

dimi

glass plate leveling with shims

https://www.youtube.com/watch?v=IN-kDf9xmi8 cnc lathe build. U channel with ribs inserted into channel. Shimming with glass plate and foil.

Eswelding

https://www.youtube.com/watch?v=6H4lT5E6KqA

Miranda

https://www.youtube.com/watch?v=bKREUByofzE remade the entire frame out of 40x40x2 steel box and TIG welded it using a technique called winging it. As a known side effect of this technique the frame is not square, straight, coplanar, or any of the required properties for the frame of a machine like this. I solved it by shimming almost everything on it with washers of different thicknesses and a lot of brute force. In the build of the aluminium one almost everything went perfect first try, in this build I had to wrestle with it a lot, way more than I'm capable to show in a single video. The machine is obviously more rigid than the aluminium one and after a lot of fiddling with it, it is surprisingly straight where it counts and seems to even be properly trammed. As a bonus at the end of the video I decided to obliterate some aluminium and steel with the wrong dull bit and completely wrong feeds and speeds.

Ronaldoverbeek

|

The Toyz

| https://www.youtube.com/watch?v=GE49sWcPMug Lathe with three pillow block bearings. |

| https://www.youtube.com/watch?v=DTf98lq6iE8 Lathe headstockcloseup. |

https://www.youtube.com/watch?v=N2QpwBT7cXw tailstock added at an angle

franco gallo

| https://www.youtube.com/watch?v=ZQXtC0P38DA. |

Here is a project I have been working on for a couple of months. The construction and mechanization of a lathe machine, I have only finished the first part of this lathe machine, i still have to place the engine , the headstock, the chuck, the tailstock and a few other things ... Each of the pieces was manufactured and hand ground. Unfortunately I could not film each and every one of the pieces made, they are many hours of work. I have had a few difficulties in this job. I have done everything self-taught, reading some books (there is not much about building lathes) and watching some tutorials on the web ... I hope I can move forward in this quarantine !! And finish as soon as possible so I can start working on iron sculptures (which I am doing this for), that is my medium and long term commissioning

Crossslide build

https://www.youtube.com/watch?v=Y09o2REiWtM

mrohny

https://www.youtube.com/watch?v=w8V8_ni5x1U lathe built with sliding angle grinder stand

Novrinal

https://www.youtube.com/watch?v=Neim58VpMPQ Homemade metal lathe episode 7 part 2, details on building bed slide and sliding rack.

https://www.youtube.com/watch?v=sMEWCtbZ9Wk&list=RDCMUC7m6NE6zh4tQX5kEPMXi2Pw&start_radio=1&rv=sMEWCtbZ9Wk&t=1854 mill playlist

https://www.youtube.com/watch?v=OP1Z1ocjDb0 mill build part.3

Mateusz Doniec

https://www.youtube.com/watch?v=JsCYdcMFDA4 slotting head for milling machine. Four brass flat bar grooved for oil flow around linear head.

https://www.youtube.com/watch?v=8_SqH73NtKM Hi! This is the second part of the film on the construction of a three-roller rolling mill for profiles and pipes, and a hydraulic press in one!

If you like this video, please leave a thumbs up and a comment so my channel can grow, Thank you! https://www.instagram.com/hobbypassionmati/

CHELLDONZ crafts and DIYs

|

accidental science

https://www.youtube.com/watch?v=w5DIehtaRM4 headstock alignment . That kind of alignment accuracy is obviously very good. Except as a general rule both the lathe head stock and tail stock are purposely misaligned by roughly .001" in 10"-12" over the length of the bed both up and towards the operator. That slight misalignment is done in an effort to build in a compensation factor for both work piece weight and cutting tool pressures. It's obviously not a perfect system since both the work piece weight and cutting tool deflection can have large changes depending on what's being done or even the cutting tool material used. So it's a best case average that helps the lathe deflect towards being more accurate instead of less in most cases. And that was very clever thinking to use a weight counter balance to remove the test bars sag due to gravity.

six part lathe build, welding and destressing. The dovetail milling for bed ways is preferred over this method.

https://www.youtube.com/watch?v=0BuqkRqqxyk This time I show how I've made the cross slide of my DIY metal mini lathe. No welding: even this part has been made without welding but joining the elements together with epoxy and pins, avoiding the risk of deformations. In this part only the cross slideway is shown while in the next episode I'll show the cross slide's sled.

https://www.youtube.com/watch?v=5rLqkpy2UQA part8b How I've made the sled of the cross slide for my home made metal lathe. Using the same technique applied for other parts of this lathe, I didn't welded the elements, rather I put them together through glue, pins and screws to avoid deformations and achieve higher quality and precision. This time I used cyanoacrylic glue (similar to superglue) in place of epoxy, because pins and screws are enough to keep the parts in place and the elements are attached together quicker.

mainakas

https://www.youtube.com/watch?v=BpH-PKBjsZ4 Homemade Mini Lathe bed & Saddle

https://www.youtube.com/watch?v=U0bb5bZ4W4g Homemade Lathe Spintle (spindle)

https://www.youtube.com/watch?v=wtMaj_2R3Dc Mini Lathe Saddle construction part 4

https://www.youtube.com/watch?v=hmWW0X7GmB8 cross slide

https://www.youtube.com/watch?v=kgGLU5gOx7Y toolpost

https://www.youtube.com/watch?v=M3sHTfaXzZA tailstock

LukaszM

https://www.youtube.com/watch?v=7z_6EXlxnBU pt.3

https://www.youtube.com/watch?v=IoBMffoPQY4 pt.4

geniusz K

https://www.youtube.com/watch?v=GeYB8TK1KwM 2mil views

https://www.youtube.com/watch?v=LDck3EccNZA Attachment for milling gears on a lathe

Techy tools

https://www.youtube.com/watch?v=wsdzl_ng6ts

Fixed tailstock

tail stock cut tapers without having to gibbs tailstock.

Shimming lathes

Renato Kretschmann

https://www.youtube.com/watch?v=jDicrbqbB4A Six videos on diy lathe build in Portuguese.

Concrete lathe

Youtube

https://www.youtube.com/watch?v=1-So7Ei8V2o by Maximum DIY mill build.

https://www.youtube.com/watch?v=KgB9rx3AhoE The bed in the lathe - this is the base - this is the basis of the machine --- and first of all the rigidity of the machine --- and also the rigidity of the headstock depend on the bed! in the absence of a cast-iron bed - it is possible to make a reinforced concrete frame and fasten or weld to it an existing bed with guides. The linear guides are milled cast iron bar bolted to steel, with the spacer wedge held in place from either side.

https://www.youtube.com/watch?v=GTEUXiDoCLc lathe rebuild 1.4mil views

https://www.youtube.com/watch?v=ptdo2bSKov0 Project no.78 diy homemade mini metal lathe machine (torno) The lathe machine is for facing bronze aluminum and alloy steel, when it comes to Mild steel its a different story i tested it and you see in the video it also can work with mild steel but it make some vibrations in the head and some weird noise that im sure its not normal. Upgrades that needs to be done to the lathe machine: use another high quality Pillow block bearing, Adding a Drill press pulley System and Changing atleast 1/2 or 3/4hp motor. I hope You Enjoy Watching My Video Building a Metal Lathe Without Using a Lathe.

https://www.youtube.com/watch?v=ckulUixg2w4 diy mini lathe and xy table with drill and threaded rod 5min. links to four videos, xy table out of flatbar . And plans at http://www.diygokarts.com/vb/showthread.php?t=18699.

https://youtu.be/Jn3E2QRhnNw Coordinate table with their own hands from scrap metal. Making flywheels, painting and assembling the xy table.

https://www.youtube.com/watch?v=yWlOh71EW1s cnc converion of mill. Today we're converting a manual milling machine to CNC. We install high quality ballscrews, ballnuts, and angular contact bearings on first the Z axis and then the Y and X axis. We also install stepper motors. This video features tips and techniques that I have developed over the past 10 conversions or so. You'll even see hardware from the first CNC conversion I ever did that was made on a manual milling machine. I learn something new every time. Please share your own CNC conversion tips and experience in the comments below.

Details: More info on the conversion kit used in this video can be found here: https://www.cncelements.com/ More info on the Precision Mathews PM-25MV milling machine used in this video can be found here:https://www.precisionmatthews.com/shop/pm-25mv/. This conversion utilizes the Centroid Acorn control board. Let me know if you would like to see video content on my specific setup: http://www.centroidcnc.com/centroid_diy/acorn_cnc_controller.html

journal bearings

lathe bearing design plain bearings or journal bearings have the best vibration damping characteristics. BEC7 roller bearings have the same tight tolerances,but not the Vibration absorption.

Router

https://www.youtube.com/watch?v=cQ332KGc-6M Lathe on router

Morse taper

http://lathecity.com/CustomDesigns/index.html

https://www.youtube.com/watch?v=g0TTQVkoOZ4 by SegmentedTurner

http://www.spsspindle.com Morse taper inserts into spindle.

https://www.ebay.com/bhp/morse-taper-sleeve

https://www.youtube.com/watch?v=a2LcYKi0o3U old tony

Mill and lathe alignment

https://www.youtube.com/watch?v=RA3Q8d4ppQs part 1 of 5 series by At-Man Unlimited Machining

https://www.youtube.com/watch?v=ZaIuHNFIFNw Rollie Daddy or Rollie Dad method from gadgetbuilder.com

http://manuals.chudov.com/Rollies-Dads-Method-of-Lathe-Alignment.pdf

cut lathe gears

skyfire

http://www.cnczone.com/forums/vertical-mill-lathe-project-log/133172-cnc-software-forum-13.html http://www.skyfirecnc.com

https://www.wikishare.us/diy-cnc-gantry-mill/ links to the pages below

Forum cnczone.com fixed gantry out of steel

https://www.cnczone.com/forums/uncategorised-metalworking-machines/222216-cnc-2.html a portable mill

http://www.mycncuk.com/threads/11206-MK1-Steel-router-build-log-1500x800x200 steel router build log FORUM

https://www.wadeodesign.com/overview--gallery.html

https://www.romanblack.com/onesec/DCmotor_xtal.htm This is a very simple way to use a cheap PIC to run a DC motor at a very slow speed, and for that speed to have very high acc

zealcnc

thick steel 7x7cm diy mill

http://zealcnc.wordjot.com/posts/the-bench-top-mill-build-part-1-the-base/ 350kg diy mill. Zaxis frame bolted to y axis with 16 bolts.

Bill T

https://www.youtube.com/watch?v=7Qah4iledMQ Spindle assembly mill.

https://www.youtube.com/watch?v=JuJoinOwI-Q&t=12s spindle with two angular contact

bearings and morse taper 3

https://www.youtube.com/watch?v=BjyfWDR6UIo commercial spindle

Mong Tran

https://www.youtube.com/watch?v=IvDpcT8E8wc home made metal lathe

Ray Makes

https://www.youtube.com/watch?v=GLNTnCgl7fk HomeMade Lathe Bearings Part 3 - self aligning roller bearings

https://www.youtube.com/watch?v=h7YX6HpmWq8

https://www.youtube.com/watch?v=huHqMryLCzs part 1

diy lathe2 and spindle

https://www.youtube.com/watch?v=DXAzJE9Zs8s Auto Reset / ELS Synchronizing Sys. (using 2 proximity sensors, 1 Pulse/Rev): Leadscrew starts running if chuck and leadscrew are at home position. Holes drilling division (Chuck lock): with steps of 10 degree. ronoverbeek@gmail.com. Headstock faceplate bearing adjusted with four gib screws, one each on square block, shifting the self aligning bearing.

https://www.youtube.com/watch?v=F7zaHQC9xtc lathe spindle.

blackburn tools

http://www.blackburntools.com/blog/south-bend-lathe-milling-attachment-part-iv/

4th axis

https://www.youtube.com/watch?v=e2vQokkLTiw

https://www.youtube.com/watch?v=D1iBJhlcO8o Vince Build

five axis

DIY lathe

Dan Gilbert lathe build , usage series youtube

http://www.laterallogix.co.za/index.php/projects/lathe/ Documenting youtube projects on lathe building.

https://www.youtube.com/watch?v=RA3Q8d4ppQs

https://desktoplathes.com

https://openbuilds.com/?id=297

https://www.youtube.com/watch?v=dRIsse05l9Y two square tubes with rails on top spaced out and tacked welded with blocks in between on both ends. Welding bends metal. geniusz K diy belt sander

https://www.youtube.com/watch?v=R_oexLiHSLI milling attachment

https://www.youtube.com/watch?v=NHYa3WfgcPY Home made lathe part 6 by uploader Home made lathe machine. Cast iron bearings over motorcycle spoke.

https://www.youtube.com/watch?v=a7lEuooQU9Y diy milling machine pt.2 (same UP)

https://www.youtube.com/watch?v=e2pPkQcueCc Tracked vehicle mini dumper. (same UP)

https://www.youtube.com/watch?v=lDgm_Kv_OJA inserts thrust bearing back to back for axial load into Tail stock , centered with headstock,then welded to axis slide. See channel for diy mill, drillpress, pipe bender. (same UP)

https://www.youtube.com/watch?v=DBKg8_2ms90 , https://www.youtube.com/watch?v=RK4gmRmuQJ8 diy mini lathe . (same UP)

https://www.youtube.com/watch?v=esAqz6bCVyQ Scrape topslide to finish, tapered gib by UP Meuller nick

https://www.cnccookbook.com/diy-cnc-machine-types-build/

http://www.hossmachine.info/cnc_conversion.html

mill Adam Maszynotwór

https://www.youtube.com/watch?v=uRiTLs6U2Po DIY 4th axis mill

Diy lathe

https://www.youtube.com/watch?v=LuriVr7cvYI&t=43s Home made lathe 9 parts by channel Id rather b welding

Gingery lathe

https://www.youtube.com/watch?v=0C_FxwKoagg DIY pipe bender, see Machine design#Make it extreme

https://www.youtube.com/watch?v=Y1IDHIcyHLY slant bed lathe, 4 axis.

https://www.youtube.com/watch?v=llLWytrtJKc concrete lathe

https://www.youtube.com/watch?v=55VlsZIuxTA , lathe banjo pt6 danshobbies.com

https://www.youtube.com/watch?v=fet7CEJDtVA timnymmy, Making a Mini Lathe Carriage Lock out of a brass block to improve facing cuts

sa suppliers

http://uniquedesigns.co.za/page13.html

Epoxy granite

lathe project

http://www.cnczone.com/forums/vertical-mill-lathe-project-log/51688-cnc-31.html

http://www.model-engineer.co.uk/forums/postings.asp?th=103541 myford mill conversion

Mill millford

https://www.youtube.com/watch?v=5CzpytZd4_A Mill the groves out of support platform out of solid slab aluminum , DIY build.

Large millford type mill build. Two x six centimeter metal plate welded onto large pipe. Fill pipe with concrete or epoxy concrete for vibration damping. Thirty kg of epoxy concrete is $120.

modelengineercouk Thought this may be of interest to other members who might have a Myford VMB milling machine and how I converted it to CNC. The machine has developed over time. Here is its current state of play...The Blue bits are mostly the added items.

https://www.youtube.com/watch?v=2wiUURbxwCA bill t, link to Machine design#Youtube uploaders factorydragon87. This mill design levers the platform, simplifying the milling head design.

Mill updyke

https://www.youtube.com/watch?v=1GKhLaHbSNY and https://hackaday.io/project/7657-cnc-mill

Mill 093 tatsu

https://www.youtube.com/watch?v=iCLz12cZbU4 How to build low cost home made CNC mill. Basically the same video of "Home made 5 axis CNC mill."

model engineer uk

http://www.model-engineer.co.uk/forums/postings.asp?th=117179 DIY lathy build

Chile lathe diy

https://www.youtube.com/watch?v=yV9ff_DAOdM From Chile large bearing 7 part series.

https://www.youtube.com/watch?v=yV9ff_DAOdM prt.5 tension the AC motor with z axis(two steel tubes over each other).

Gear thread cutting

book "Gear cutting with the shaper+ by base circle https://www.youtube.com/watch?v=so4O_yxUfCE

http://www.youtube.com/watch?v=KHZFj8qAycE from http://www.mainsteam.co.uk/steam_launch.htm

http://www.youtube.com/watch?v=xRmQpSGUAY8 Stationary mill rotating involute gear cutter. The lathe moves the blank through the cutter, cutting a v-shape. Two stepper motors needed , one rotates the blank, other moves platform forward.

http://www.youtube.com/watch?v=-2-uOi1uFJU This method preferred mill and lathe combo.

http://www.youtube.com/watch?v=ie7dNOLgno0 Spinning tap in chuck cuts worm wheel . Use one geared DC motor mounted on platform, stepper provides x-axis. The blank is fits over vertical shaft, spinning freely.

4th axis

https://www.youtube.com/watch?v=jkgmjIlOVKc making a gearbox worm for a fourth axis, oil seals.

Stepperhead

http://www.lathes.co.uk/stepperhead/ Designed and built by Alan Jackson, the Stepperhead is an attempt to combine, in one unit, the range of facilities found in a medium sized lathe and a small vertical/horizontal milling machine. In the 1950s David Urwick had designed and built the ingenious and versatile Metalmaster http://www.lathes.co.uk/metalmaster/ , a device that combined a lathe and milling machine without unduly compromising the attributes of either.

http://www.lirtex.com/robotics/diy-cnc-machine/

http://twilightrobotics.com/cnc/cncnot1 how not to make a cnc

lathe 1

http://www.youtube.com/watch?v=7MUxivrx_MU Harbor freight mini lathe

http://morgandemers.com/ making a lathe face plate with aluminium casting

http://www.youtube.com/watch?v=spwfHuNSJXA

http://www.youtube.com/watch?v=oJHDSY7tZ8c quick change toolpost

Bevel blocks

http://www.youtube.com/watch?v=pTArvTJt5eI build hand tool lathe Building a Hand Drill Lathe (How To)

http://www.youtube.com/watch?v=7wejoxolvjw Homemade Wood lathe Duplicator using an angle grinder

King Arthur wheel on grinder for lathe work DIY lathe for woodwork

http://www.youtube.com/watch?v=dz8dxXfm2hs Lathe from old DRILLPRESS

http://www.youtube.com/watch?v=40vQHTt9s-A micro or mini lathe

http://www.youtube.com/watch?v=lwmpFI1kDww Homde made lathe BEVEL block bearings, shows pictures .

Sherline

check out sherline 4000 mini micor lathe Lathe face cutters

milling http://www.cnczone.com/forums/linear_rotary_motion/189054-machining_large_worm_gear.html

http://www.youtube.com/watch?feature=player_detailpage&v=J0o3W4_LRBw&t=494 ,

http://www.youtube.com/watch?v=xRmQpSGUAY8 gear making

http://www.youtube.com/watch?v=oSeMX9SZXXY helical gear is cut on lathe. this is preferred can be reproduced.

http://www.youtube.com/watch?v=HAtziCsUj5Q Helical with CNC machine.

hobbynut channel

http://www.youtube.com/watch?v=8UBxNPbg0ls CNC or mill(manually) cutting worm gear. adapt with DIY drill lathe . Hand drill rotates at high speed with a cutting tool, lathe part is done at angle to cut worm pattern out of plastic. The angle of the drill bit determines how thick or thin the worm gear edges are.

tutorial

http://www.mini-lathe.org.uk/12-hobbing-the-worm-wheel.shtml telescope worm wheel

Concrete lathe

Bolt steel diy lathe to concrete for Vibration absorption. Concrete, like cast iron functions as a mechanical low pass filter.

http://opensourcemachinetools.org/concrete-lathe/ links to http://concretelathe.wikispaces.com/Current+Design+Drawings and http://makezine.com/projects/the-multimachine-150-12-swing-metal-lathemilldrill/

Lathe brands

http://www.africamachinetools.co.za/

http://machinetoolexchange.co.za/product/dean-smith-grace-lathe/

http://qtul.com/cnc-rotary-tables/accessories/80mm-3in-chuck-with-backplate.html $120

forums

https://www.homemodelenginemachinist.com/threads/grinding-spindle.33281/

https://www.practicalmachinist.com/forum/threads/plain-bearing-spindle-design.423053/

Links

https://www.youtube.com/@innovationtime20 lathe build eight part series. Align spindle with rails using two pillow block bearings, finally fix using Moglice or jbweld type paste the angular contact bearings and its surface plate to on the outside of the metal box for axial and radial load bearing. Pillow block bearings alone have to much play for precision work.(https://www.practicalmachinist.com/forum/threads/are-there-rigid-pillow-block-bearings.315832/) , https://thebigbearingstore.com/type-e-series-1/

https://youtu.be/vSG_BEtArRE In this video you will watch the construction of a very beautiful lathe. I will try to show every detail. I really liked the lathe I made. I will develop this machine more. I will continue to share your videos on this channel. In this video, I only showed how to make a lathe, I will show you how to make a belt sander in the 2nd part. If you write your ideas that you want me to do on this machine in the comments section, I will use these ideas during the development phase. There will be studies that may be of use to you. Have a good time, my friends. Homemade Lathe and Strip Belt Sander combination (Part 1)/ DIY lathe otthon lathe the golden country diy projects lathe diy lathe machine Homemade lathe machine homemade lathe how to make a lathe machine wood lathe sander belt sander strip sander Strip belt sander making machine how to do it yourself asmr white noise sleep Asmr machine sounds DIY #diy #do it yourself build our machine engineering bendy and the ink machine mini lathe mini wood lathe homemade woodworking lathe mini woodworking lathe making wood lathe

https://youtu.be/obonMNBxpjM Mr.Craft diy in this video I will show you how I made a homemade cnc machine, of course, it was not easy to make such a machine at one time. I want to share with you how to make a large cnc machine from scratch to the final result. I like such homemade projects, and it fits very well into my channel, because I really needed a good cnc machine.

https://youtu.be/LZDO9fyFSk0 This is my Homemade Lathe Machine,this Lathe is made up of 75% scrap metal,,I made this machine because, sometimes in my workshop I need a small machine jobs not only small jobs but also light jobs that I need to my DIY/Homemade projects. From https://www.youtube.com/@Workshophobby2201

https://www.youtube.com/watch?v=9pXsedA8PD8&t=64s from @robertsteinwandel6658

https://www.youtube.com/watch?v=flwyxP2k6l8 diy chuck

Lathe concrete , lathe spindle

jeremy makes things

https://www.youtube.com/watch?v=QI8_Hxq_aK4 homemade mini milling machine part-1 from https://www.youtube.com/@KnyTech

https://www.youtube.com/watch?v=qhPoMFusJ30 , https://www.youtube.com/@powellfab.3357

https://www.youtube.com/watch?v=wGERjsbcMIw by https://www.youtube.com/@a-cnc-f (Five axis mill). cnc lathe build with epoxy granite

https://www.youtube.com/@CNCUmbau cnc lathe

https://www.youtube.com/watch?v=8NZ7_wrVbSE xincao diy metal lathe part 11

https://www.youtube.com/watch?v=VwNZ5Q7vzv4 kurtscottage'

https://www.youtube.com/watch?v=sG5iiL9irnk knytech

https://www.youtube.com/watch?v=IsVqWVxyB5g run cnc at home

https://www.youtube.com/watch?v=KiaJMPBQAO8 DSMASCHINENBAUTEILE

https://www.youtube.com/watch?v=yswrih6u9v4 kvechannel and https://www.youtube.com/watch?v=XqryVlmIUIo headstock building, playlist of lathe building

https://www.youtube.com/watch?v=ZJM7aQ3H338 metalmusings eleven part mill build, epoxy granite

https://www.youtube.com/watch?v=JoTPPUVU8uw Alexandr Metal Works Surface grinder, 5 part vid

https://www.youtube.com/watch?v=n6-CfGqoVsQ workshopfriend

https://www.youtube.com/watch?v=XqwBb3mKVzo made in garage In this video, I made a cross slide, a chisel holder, installed an electric motor and a frequency inverter that should convert one phase 220 volts to three phases 380 volts. I hope this will be the last part of the construction of my homemade lathe for metalworking.

So, at first I thought to make a transverse feed on the basis of rail guides for CNC machines, but at the moment when I decided to buy them, the war in Ukraine began, and it was impossible to buy and deliver something. The same is true with buying from China. I started to do everything on my own - angles, plates, welding ... But I think in time it will be possible to redo. Then I took the cutter holder, made one cutter 25 mm high, the design turned out to be massive and strong, as for me. The last stage is painting and assembling the structure together. Well and the most interesting, it is the first shaving and test of my self-made lathe on metal. Watch the video, rate, comment on what you like or not.

The lathe is a very useful thing for any craftsman, in the garage or workshop will be an indispensable helper.

What you need to make a metal lathe in your home workshop - a piece of channel, a pair of angles, profile pipes, electric motor, lathe chuck, wide thrust bearing, drive pulleys. And from the tool, it is an angle grinder, drill or drilling machine, files and welding machine, and most importantly a great desire to do something with your own hands.

Not 1K62, 16k20, TV-4, Izh250. The self-made lathe on metal is made of scrap metal.

https://www.youtube.com/watch?v=dHRjYQW9j5w wasteland workshop mill build using commercial xy axis

https://www.youtube.com/watch?v=SdhnnC3YtG4 linear guides(no music)

https://www.youtube.com/watch?v=BZ3vIzjcZ2U workshop from scratch The machine is very helpful in making the widening of steel wheels, for the drive I used an electric motor with a gear, the engine speed was additionally reduced so that it was possible to weld not only with the mig method but also with the tig method. With such a widening of the wheels, work must be done very carefully, without haste, weld with high current to perform remelting. The wheel that I widened is much harder to widen than the regular wheel, but thanks to the rollers, I managed to make this wheel perfectly, the rollers help to center and align the wheel axis

https://www.youtube.com/watch?v=6FBkKRp4HM4 workshop from scratch The frame made of 32mm tube diameter, the brakes and suspension parts are from Yamaha YFM700 ATV Quad, universal shock absorber for ATV Quad. I also changed the drive to make the quad slower and stronger. The front rack is one tooth smaller, the front rack is 4 teeth larger.

After completing the project and the first test drive, I was pleasantly surprised by the ride, the quad does not reach high speeds anymore, but has a very good acceleration. Ride this ATV for great fun.

https://www.youtube.com/watch?v=Xfm0t0SrAWo channel seabash 40min cnc lathe vid

https://www.youtube.com/watch?v=ZwOHX3pAYyg scrap to lathe chuck 40mins, by Isle Vlogs

https://www.youtube.com/watch?v=94-RQ2gXa-4 channel my chu create shared by homemadetools.net

https://www.youtube.com/watch?v=isVQMHmzHNo machine thinking channel

https://www.youtube.com/watch?v=Y7OT4vFevxM channel wood to wonder

https://www.youtube.com/watch?v=z67A3Myy6XM channel HOMEMADE MADNESS . In this video i'm showing how i built my homemade metal cutting lathe mk2 from scratch! challenging myself by only making it with basic tools. It probably won't be the most accurate machine ever, but surely good enough for me.

injection molding machine build channel Action BOX

https://www.youtube.com/watch?v=LUggzM0JOlI channel 'robrenz precision tool room spindle.

https://www.youtube.com/channel/UCTe6GWDa5SF_dCTqpKMsZmg andy's machines. See his Electric discharge machine build.

https://www.youtube.com/watch?v=Jj6WAY0MS7o homemade lathe part 1 , channel sửa chữa & chế tạo

https://www.youtube.com/watch?v=4pIPrrcwM0E Maker B Four stroke engine build

https://www.youtube.com/watch?v=rdkoTN094bA lathe compound adjustment modification by we can do that better channel

https://www.youtube.com/watch?v=vNyrYMU_EhI micro lathe by table top machineshop

https://www.youtube.com/watch?v=KX6Y-biN-2U&t=322s channel Vincebuild

https://wiki.opensourceecology.org/wiki/Open_Source_Lathe

Machine design